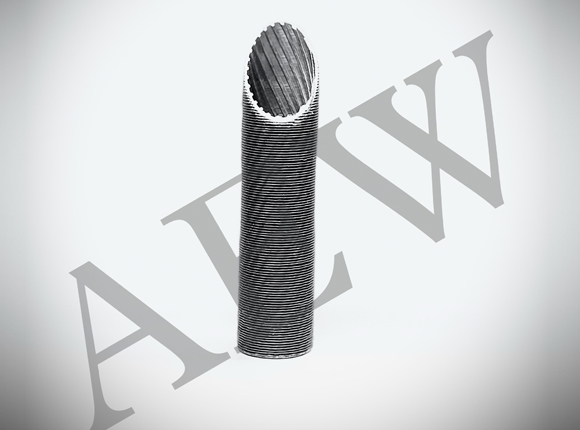

Aluminium-Brass Finned Tubes are processed out of plain tubes conforming to SB-111 UNS No.C-68700 in Annealed Condition (061).

Plain Aluminium-Brass Tubes for processing Fin Tubes will be procured from Indian Plain Tubes manufacturers only, as per the code and specification. Plain Tubes will be procured for finning, duly Hydro Tested and Eddy Current Tested as per material specification and code, from plain tube manufacturers only.

If customer require, we will procure plain Aluminium Brass Tubes for finning, duly inspected, approved and released by customer or Third Party Inspection Agency, at plain Tubes manufacturer's end.

The main characteristic of Aluminium Brass is its high resistance to impingement attack. Tubes of this alloys are recommended for use in Marine and Land Power Stations, in which cooling water velocities are high.

| Material [ MOC ] | Aluminium-Brass : SB111 UNS NO. C - 68700 |

| Finning | As per SB - 359 |

| Diameter | 15.88mm, 19.05mm, 22.20mm to 25.40mm |

Wall thickness

| 1.25mm up to 3.25mm |

|

| No. of Fins per Inch | 19, 26, and 32 FPI |

- Aluminium-Brass Low Fin Tubes are available with exact lengths required by customer.

- Aluminium-Brass Low Finned Tubes are available with plain portion at both ends, as per customer specification.

- Aluminium-Brass Fin Tubes are available with Intermediate landings (plain portion for baffle sheet support), as per customer requirement.

- Aluminium-Brass Fin Tubes will be supplied, duly Hydro Tested, after finning.

- Aluminium-Brass Fin Tubes will be supplied in "As Finned Temper".

- Aluminium-Brass Fin Tubes will be supplied duly Stress Relieved on in-house Electric Conveyor Belt Furnace, as per SB-359, on customer specific requirement.

- We shall supply Aluminium Brass Low Fin Tubes, duly inspected and approved by Customer or any Third Party Inspection Agency, as per customer specific requirement, at our end before dispatch.

- We shall provide MTC along with our supply documents.